Solar Panel Encapsulants Directory

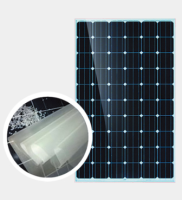

Welcome to the world’s most advanced solar EVA product directory. Panel manufacturers can use our advanced technical filters to find the exact solar encapsulant that match their needs. We have collated EVA data from manufacturers from all around the world into a common template, allowing you to compare and review EVA films easily.

Continent

Thermal Shrinkage (Width /TD) ≤

Peel Strength (Encapsulants - Glass) ≥

Peel Strength (Encapsulants - Backsheet) ≥

Elongation ≥

Width ≤

Hardness (Shore A)

Gel Content ≥

Light Transmittance ≥

Melting Point

Vacuuming Time

Lamination Time

Solar Panel Encapsulants Directory

(139 Individual Encapsulants Models)

-

Type: Standard Cure Tensile Strength: -- Thickness: -- Thermal Shrinkage (Length / MD) ≤: -- Region: China

3M white film, High reflectivity helps increasing power efficiency especially for single glass & double glass module. Meanwhile, it plays an important role in improving the module CTM, increasing the power output, especially for double glass modules.

-

Type: Fast Cure Tensile Strength: 10 MPa Thickness: 0.65 ~ 0.6 mm Thermal Shrinkage (Length / MD) ≤: 2 % Region: India

-

Type: Standard Cure Tensile Strength: -- Thickness: -- Thermal Shrinkage (Length / MD) ≤: -- Region: China

√ High Transmittance,Higher Power Output

√ Thermosetting,No Creep, Especially Suitable for Glass-Glass Modules

√ No Acetic acid,No corrosion , Long Lasting Power Output

√ First choice encapsulant films for type N or P double-sided cells

√ Lower MVTR,Excellent Damp-Heat Stability

√ High Compatibility ,Good Capacity with c-Si, Cd-Te & CIGS Modules

-

Type: Fast Cure Tensile Strength: -- Thickness: 0.2 ~ 0.8 mm Thermal Shrinkage (Length / MD) ≤: 3 % Region: China

Anti-PID EVA encapsulation film

Excellent water vapor barrier performance

Weather resistance

Higher cost advantage

Better anti-PID characteristics

Better peel strength retention

-

Type: Fast Cure Tensile Strength: 7 MPa Thickness: -- Thermal Shrinkage (Length / MD) ≤: -- Region: Korea

-

Type: Fast Cure Tensile Strength: 5 MPa Thickness: -- Thermal Shrinkage (Length / MD) ≤: -- Region: Korea

-

Type: Fast Cure Tensile Strength: -- Thickness: 0.2 ~ 0.8 mm Thermal Shrinkage (Length / MD) ≤: 3 % Region: China

White eva encapsulation film

Improve the effective utilization rate of visible light

Increase generating power

has high reflectivity retention rate and high peel strength retention rate for

long-term use.

-

Type: Fast Cure Tensile Strength: -- Thickness: 0.2 ~ 0.8 mm Thermal Shrinkage (Length / MD) ≤: 3 % Region: China

Co-extrusion white poe film

Perc、topcon single/double glass photovoltaic module

Reduce white film spillage after component lamination

Low water vapor transmission rate

Reduce micro-cracks during cell lamination

High reflectivity retention

High weather resistance

-

Type: Fast Cure Tensile Strength: 18 MPa Thickness: 0.2 ~ 0.8 mm Thermal Shrinkage (Length / MD) ≤: 3 % Region: China

Thermoplastic adhesive film tpo

Has the advantages of low packaging temperature and low water vapor transmission rate

Maintains excellent weather resistance and good adhesion

Can be widely used for the packaging of perovskite batteries and thin film battery modules

-

Type: Ultra Fast Cure Tensile Strength: 16 MPa Thickness: 0.45 ~ 0.9 mm Thermal Shrinkage (Length / MD) ≤: 3 % Region: China

Anti PID PID EVA film (SV-15,296P&SV-15,297P)

Can reduce the risk of component PID

Excellent weather resistance (including high temperature, high humidity, ultraviolet, etc.)

Low shrinkage to ensure component stability during lamination

Fast curing, improve component lamination production efficiency